FAQ

FAQ

Protect your assets, equipment, and what matters most with our reliable structures. So strong, so attractive, and ready for anything.

What's The Average Turnaround Time For Installation?

The average turnaround time for installation is 4-8 weeks. Some factors that may affect lead times can be but are not limited to the area, State, weather (including season changes) and Size of the Building.

Please contact the office with your lead time questions at 801.406.9508

Am I Required to Get a Permit?

Due to the distinct laws for each County/State regarding permits, we do not keep such records on hand, each customer is responsible to find out if they need a permit or not from their Building Department, Quality Carports, Inc., will not be responsible to obtain customers building permit if they are required. Please visit the following link to learn more about building permits.

What Are Some of the Items on the Construction of a Carport?

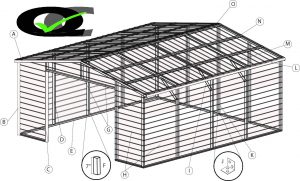

Below you will find an image showing some of the items that go into building a vertical roof carport or garage. These items are the same for both regular style and a-frame style carports except for the purlins.

(A) (B) (C) (L) “L-trim”: Is used on Regular Styles that are open or with a horizontal end(s), A-Frame & Lean-to Style buildings that are open with vertical roof, horizontal roof & side(s), It is also used in all frame openings (ex., overhead, roll-up and walk-in doors), on windows “J-trim” is used.

(B) “Corner trim” is used on enclosed A-Frame & Lean-to Style buildings with vertical roof, side(s) and end(s) instead of the L-trim.

(D) (K) Post (uprights) can be 14 ga. or 12 ga. galvanized square tubing, they come in lengths of 5′ up to 18′.

(E) (F) Bottom rails are made from our standard 20’ long 14 ga. galvanized square tubing included are 7″ pre-welded inserts (sleeves) by our production department, these are made of 14 ga. (either 2″ or 2 ¼”) galvanized square tubing that connect the post to the bottom rail; with optional extensions of 5’ to achieve the length desired.

(G) Header bars and vertical supports for overhead doors, roll-up doors are made of 14 ga. either 2″ or 2 ¼” galvanized square tubing, these are used to install the door tracks and the electric opener system on overhead doors.

(H) 29 ga. panels come standard on 13 different colors for the roof, sides and ends (26 ga. special order panels are also available with a 20-year warranty.)

(I) 18 ga. 2 ½” x 1 ½” channels are used as knee braces on buildings up to 30′ wide and as peak braces on buildings up to 19′ wide.

(J) “L” Brackets are installed to join two pieces of square tubing together where there will not be a pre-welded connection or sleeve.

(M) Trusses (bows) are pre-fab of galvanized square tubing 14 ga. or 12 ga., the size varies by the width of the building and they can range from 8’ wide up to 30′ wide.

(N) 4 ¼” x 1 ½” 18 ga. hat channels are used on a-frame styles with vertical roof & sides and on regular style with the vertical end option.

(O) 11′ Ridge cap trim is used only on a-frame with vertical roof style.

What Are Some of the Details That I Need to Provide to get an Accurate Estimate for my Carport(s)?

To better assist you, we will need to know the following information of the carport(s) you are interested on purchasing such as:

- Width

- Length

- Height

- Enclosures

- Installation Surface

- Size & Quantity of Doors

What Are Some of the Building Sizes Available and How is the Framework Measured?

Our standard size starts at 12’W and jumps to 18’W. After that, the width goes up by increments of 2′. For length, our size starts at 20’L and increases by increments of 5′.

While we have standard sizes and packages available, we can customize the structure to meet your needs.

Here’s an example of how we measure the frame work (ex. on a carport that is 18’ W x 26’ L, the width would be 18’ from outside to outside and the length would be 25’ from end to end, the standard horizontal roof has an overhang of 6” at each end and thus the roof measures 26’ in length while the structure remains at 25’ long, this ensures that water will not run back inside the building.)

What Are Some of the Methods Used by Quality Carports to Anchor a Structure Down?

There are five methods of anchoring offered by Quality Carports, concrete bolts for when mounting to a cement pad or footers, 18″ asphalt anchors (for buildings up to 30’ wide), 30” or 48” auger mobile home anchors to tie down to dirt & a 30” rocky type anchor when the surface is rocky. We highly recommend that the proper number of anchors be purchased to certify the structure if you live in a windy area, please see our page related to wind and snow certification for more info.

What is the Max. Available Wall Height?

The max available wall height is currently 18 feet tall. Our crews are properly equipped to install anything up to12 feet height. However, we require a forklift on any building taller than 12 feet. Forklift rental is buyer obligation.

Do I Need to Do Any Site Preparation Prior to my Installation?

To properly install our products, the site must be squared and leveled within 2” before a cut fee may be applied. Due to varying requirements by each county/city, every customer is responsible for any necessary permit(s) required (if applicable) for the proper installation of the structure. This helps us provide an economical product and ensures quick installation.

What Size of Pad Do I Need for My Building if I Want to Install on Concrete?

Since we measure our units by the framework and not the roofline, we highly recommend the foundation to be 6” wider and longer. For example, if your building is an 18′ W x 26′ L the structural footprint would be 18’ W x 25′ L outside to outside. The foundation then needs to measure a minimum of 18’ 6” x 25’ 6”. This will allow our crew to be able to properly anchor the building down without the risk of cracking the slab.

Does Quality Carports Offer a Better Price When Ordering Directly?

We would be more than happy to assist you with your questions and placing your order. However, as a company, we believe on promoting the local economy in your area and we strongly encourage you to visit one of our local distributors in your area (where applicable). This does not affect our prices.

What Are the Advantages of Purchasing a Vertical vs. Horizontal Roof?

While paying a bit extra for a vertical roof the advantages of going vertical vs horizontal are notorious, a vertical roof will displace snow and water more easily than a horizontal roof since the ridges of the panels run from the peak down to the sides of the building, instead of front to back like a horizontal roof would which can allow for water or snow to pond on the roof. Going vertical also allows water or snow to drain to the sides instead of the front or back where most doors or frame outs are located.

What is the Average Space Between Each Truss?

The average space between each truss is 4’ to 5’ on center. This could vary depending on other contributing factor(s) such as a different snow load certification. The option to add more trusses and close the space between them is available, adding more trusses does not necessarily mean a heavier snow load will be achieved.

How Tall Does my Building Need to be to Accommodate a Garage Door?

When installing a noncommercial garage door, the wall height must be 1’ taller than the doors. When installing a Commercial garage door, the wall height must be 2’ taller than the door.

What's is the Estimated Height to the Center Peak on my Building?

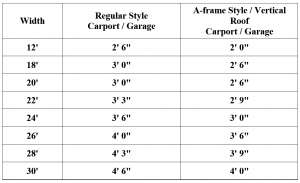

We measure the height of our building(s) from the top of the base rail to the bottom of the eave where the side posts meet the welded sleeves on the trusses, since our roof(s) have a min. of a 3/12 pitch, then to calculate the height to the peak on a building that is 20’ wide by 7’ tall you would add 3’ to the wall height resulting on an approx. height of 10’ to the peak. (Please refer to the chart below for reference.)

What Are the Acceptable payment methods, and do You Offer Financing?

The current accepted payment methods are Cash, Money Order or a Cashier’s Check (made payable to “Quality Carports”). We do not accept personal or business checks. We also accept Visa and Mastercard (a 2.5% fee will be applied to the amount).

We unfortunately are not offering Financing at this time.

Are You Guys Able to do Any Additions on My Existing Structure?

We can do additions on any of our buildings, please be aware that a fee will apply if such addition is less than $1,000.00. Due to framework differences, we are unable to do any additions to the length of the building or on any structures that weren’t installed by Quality Carports (please keep a record of your purchase for validation purchases).